Constructing a Lofted Shed: A Comprehensive Guide

This document provides a detailed, step-by-step guide for constructing a lofted shed. The instructions are designed for individuals with basic carpentry skills and access to appropriate tools. Safety precautions should be prioritized throughout the entire construction process. Always consult local building codes and regulations before commencing any construction project.

Phase 1: Planning and Preparation

1.1 Site Selection and Preparation

The initial step involves meticulous site selection. Consider factors such as accessibility, proximity to utilities (if required), drainage, and sun exposure. The chosen location should be level and free from obstructions. Clear the area of vegetation, debris, and any potential hazards. Mark the shed's perimeter using stakes and string to ensure accurate dimensions. Compaction of the ground may be necessary for a stable foundation, depending on soil conditions.

1.2 Design and Materials

Determine the dimensions of your lofted shed, taking into account intended storage needs and available space. Detailed plans, including precise measurements for all components, are crucial. These plans should account for the shed's overall height, the height of the loft area, and the dimensions of the walls, roof, and floor. Choose appropriate materials, considering factors like durability, cost, and aesthetic preferences. Common choices include pressure-treated lumber for the framework, plywood for sheathing, and asphalt shingles for roofing. Ensure you have sufficient quantities of all necessary materials before commencing construction.

Material List Example (adjust based on your specific design):

- Pressure-treated lumber (4x4 posts, 2x4 framing, 2x6 rafters)

- Plywood (for sheathing, flooring, and loft floor)

- Asphalt shingles

- Concrete blocks or pier footings (for foundation)

- Nails, screws, and other fasteners

- Exterior-grade paint or stain (optional)

- Door and window materials

- Hardware (hinges, handles, locks)

1.3 Obtaining Permits and Inspections

Check with your local authorities to determine whether building permits are required for your shed project. Submit all necessary documentation and obtain the required permits before initiating any construction activities. Schedule inspections at designated stages of the construction process to ensure compliance with building codes and regulations. Failure to comply with these regulations can result in penalties or even demolition.

Phase 2: Foundation Construction

2.1 Foundation Preparation

The foundation is critical for the structural integrity of your shed. Prepare the site by excavating holes for the foundation supports (concrete piers or concrete footings) according to your plans. The depth and spacing of these supports will depend on local soil conditions and the shed's size. Ensure the holes are level and properly sized to accommodate the chosen foundation type.

2.2 Pouring the Foundation

Place the foundation supports (concrete piers or blocks) within the excavated holes. Ensure they are level and plumb. For concrete piers, follow the manufacturer's instructions for mixing and pouring the concrete. Allow sufficient time for the concrete to cure completely before proceeding to the next phase. This curing time typically ranges from 24 to 72 hours, depending on weather conditions.

Phase 3: Frame Construction

3.1 Floor Framing

Construct the floor frame by attaching pressure-treated lumber to the foundation supports. This will create the base for your shed floor. Use appropriate fasteners and ensure the frame is level and square. Employ a level and measuring tape to guarantee precision and avoid structural issues. The floor joists should be spaced according to building codes, typically 16 inches on center.

3.2 Wall Framing

Assemble the wall frames using 2x4 lumber. Construct each wall section separately on the ground, ensuring squareness and accurate measurements. Use appropriate fasteners and bracing to maintain stability during assembly. Once the wall frames are complete, carefully raise and secure them onto the floor frame. Use temporary bracing to maintain the wall's vertical position until the roof is installed.

3.3 Loft Framing

Construct the loft framing after the walls are in place. This will typically involve installing beams or joists to support the loft floor. These supporting members should be appropriately sized to handle the anticipated load, and the spacing should adhere to building codes. The loft floor should be strong enough to support the intended weight. Consider using plywood or OSB for the loft floor. Ensure proper connections between loft framing and wall framing to ensure stability.

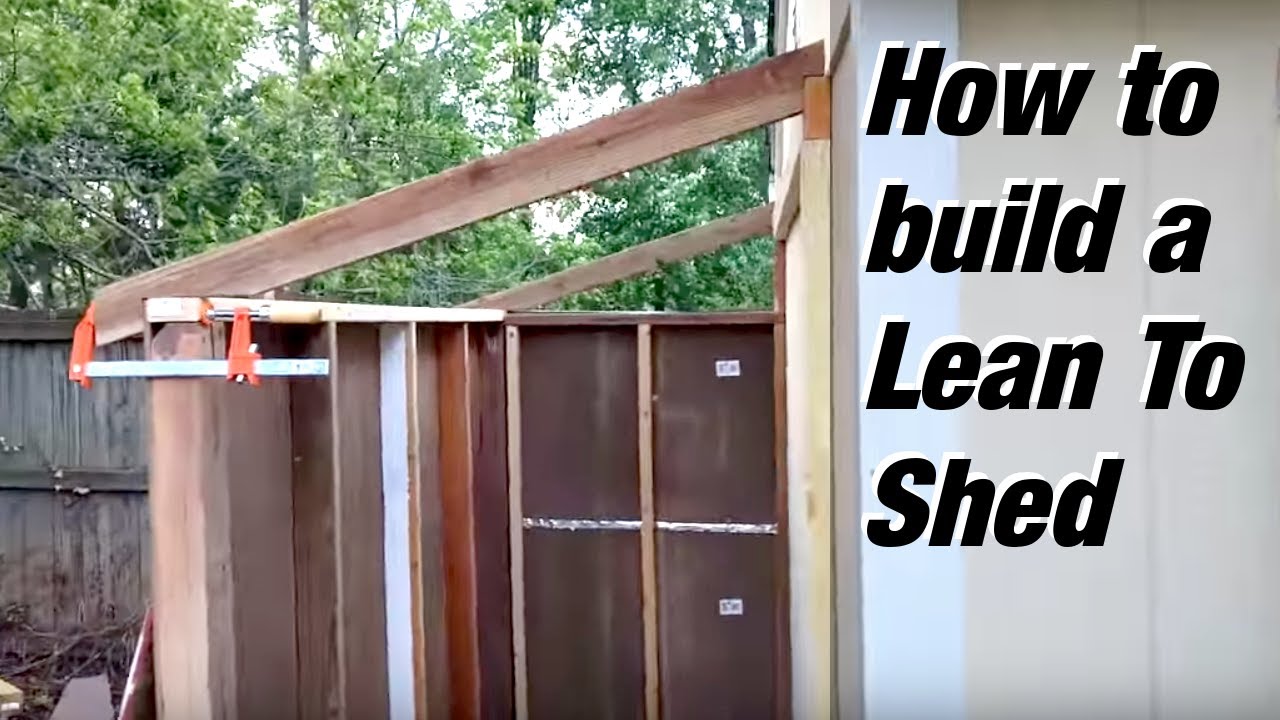

3.4 Roof Framing

Construct the roof framing using rafters or trusses. The design of the roof will depend on your plans. Install the rafters or trusses securely, ensuring they are properly aligned and spaced. Use appropriate fasteners and bracing to ensure structural integrity. For added stability, consider adding ridge boards and purlins.

Phase 4: Sheathing and Roofing

4.1 Wall Sheathing

Apply plywood sheathing to the exterior walls. Ensure proper alignment and secure fastening. Use appropriate nails or screws for the chosen sheathing material. Pay close attention to sealing any gaps or cracks to prevent air leaks and water damage.

4.2 Roof Sheathing

Apply plywood or OSB sheathing to the roof frame. Ensure proper alignment and secure fastening. Use appropriate nails or screws for the chosen sheathing material. This layer provides a solid base for the roofing material.

4.3 Roofing Installation

Install the chosen roofing material according to the manufacturer's instructions. For asphalt shingles, start at the bottom of the roof and work your way up, overlapping each shingle appropriately. Ensure proper ventilation to prevent moisture buildup.

Phase 5: Finishing Touches

5.1 Exterior Finishing

Apply exterior-grade paint or stain to protect the wood from the elements. This will enhance the shed's appearance and longevity. Choose a suitable finish that protects against moisture and UV damage.

5.2 Door and Window Installation

Install doors and windows, ensuring they are properly aligned and secured. Use appropriate hardware, including hinges, handles, and locks. Caulk around the frames to prevent air leaks and water damage.

5.3 Interior Finishing

Finish the interior of the shed according to your preferences. This may include installing insulation, drywall, or paneling. Consider adding lighting and electrical outlets if needed. Remember to comply with all electrical codes and regulations.

Disclaimer: This guide provides general instructions. Specific techniques and materials may vary depending on individual designs and local building codes. Always consult professional resources and adhere to safety regulations throughout the construction process. Incorrect construction could result in structural failure.