Building a Lean-To Shed: A DIY Project for Maximum Impact

Constructing a lean-to shed presents a rewarding DIY project, offering significant storage solutions and aesthetic enhancements to any property. This comprehensive guide details the planning, materials acquisition, and construction phases, enabling even novice DIY enthusiasts to successfully complete this undertaking. While demanding time and effort, the resultâ€"a functional and visually appealing addition to your propertyâ€"justifies the investment.

Phase 1: Planning and Design

Meticulous planning forms the cornerstone of any successful construction project. Failing to adequately plan can lead to costly errors, material waste, and ultimately, a subpar outcome. This phase necessitates careful consideration of several critical aspects.

Site Selection and Assessment

The chosen location significantly impacts both the practicality and aesthetics of your lean-to shed. Factors to consider include:

- Proximity to existing structures: Ensure sufficient space for construction and future access. Consider proximity to power sources if electrical fittings are planned.

- Ground conditions: Evaluate the soil type to determine the need for a concrete foundation or alternative groundworks. Poor drainage can lead to foundation instability.

- Sunlight and shade: Assess the amount of sunlight the shed will receive throughout the day. Excessive sunlight may necessitate ventilation or insulation considerations.

- Local regulations and building codes: Verify compliance with local building regulations, zoning ordinances, and any homeowner's association guidelines. Obtaining necessary permits is crucial to avoid potential legal issues.

Dimensions and Design Considerations

Determine the desired dimensions of your lean-to shed based on your storage needs. Consider both the length and width, ensuring sufficient interior space while maintaining proportionality to the existing structure it will be attached to. The height should be sufficient to allow comfortable access and storage. Detailed sketches are highly recommended, incorporating specific dimensions and material specifications.

Consider the following design elements:

- Roof pitch: The angle of the roof affects water runoff and overall aesthetics. A steeper pitch is better for areas with heavy snowfall.

- Door placement and size: Ensure easy access to the shed's interior. Consider the size and location of the door in relation to the available space.

- Window placement: If desired, windows can provide natural light and ventilation. Their placement should maximize natural light while minimizing heat gain in hot climates.

- Material selection: Choose materials that are durable, weather-resistant, and aesthetically pleasing. Common choices include pressure-treated lumber, plywood, and metal roofing.

Phase 2: Materials Acquisition and Preparation

Accurate material estimation is paramount to avoid unnecessary expenses and project delays. Create a detailed list of materials required, including lumber, fasteners, roofing materials, and any additional components such as windows or doors. Consider purchasing materials with a small margin of error to account for potential waste or unforeseen circumstances.

Lumber Selection and Treatment

Pressure-treated lumber is highly recommended for its resistance to rot, decay, and insect infestation, especially for components in direct contact with the ground. Specify the dimensions of required lumber accurately, ensuring appropriate strength and durability for the structure. Check for any defects before purchase and consider pre-cutting longer pieces to manageable lengths to simplify construction.

Roofing Material Selection

The choice of roofing material impacts longevity, cost, and aesthetics. Common options include asphalt shingles, metal roofing, and polycarbonate sheets. Asphalt shingles offer a cost-effective solution, while metal roofing provides superior durability and longevity. Polycarbonate sheets provide excellent natural light transmission.

Phase 3: Construction

The construction phase demands careful adherence to the pre-determined plan. Proceed methodically, ensuring accurate measurements and secure fastening at every stage. Consider using appropriate safety equipment throughout the entire process.

Foundation Preparation

The foundation type depends on ground conditions and local regulations. A concrete slab foundation provides a stable and durable base, while alternative options include gravel pads or pier footings. Ensure the foundation is level and appropriately sized to support the shed's weight.

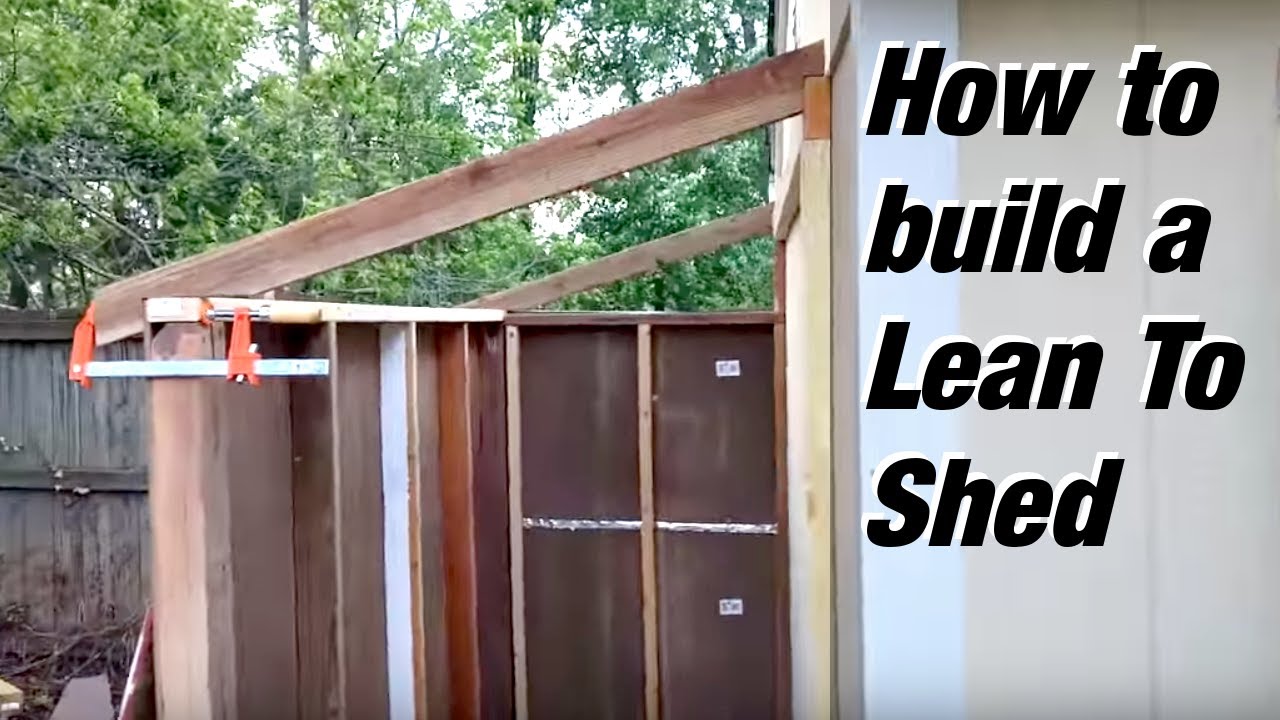

Framing and Wall Construction

Construct the frame according to your design specifications, ensuring accurate measurements and square corners. Use appropriate fasteners to secure the framing members. Sheathe the walls with plywood or other suitable material, ensuring proper alignment and fastening. Consider adding insulation for better climate control.

Roof Construction

Construct the roof framing, ensuring proper rafter spacing and support. Install the chosen roofing material, ensuring proper overlap and sealing to prevent leaks. Ensure sufficient overhang to protect the walls from water damage. Consider adding a ridge vent for improved ventilation.

Finishing Touches

Install the door, windows (if applicable), and any additional features. Apply a protective sealant or paint to the exterior to improve weather resistance and aesthetics. Clean up the construction site and dispose of all debris responsibly.

Phase 4: Post-Construction Considerations

After completion, it's crucial to conduct a thorough inspection, ensuring all components are securely fastened, and the structure is stable and watertight. Regularly inspect the shed for any signs of damage or deterioration, addressing issues promptly to maintain its longevity.

Maintenance and Upkeep

Regular maintenance is key to prolonging the lifespan of your lean-to shed. This includes periodic inspections for any signs of damage or decay, addressing any issues promptly. Regular cleaning and applying protective coatings will help prevent deterioration and preserve its appearance.

Building a lean-to shed is a challenging yet rewarding endeavor. Through careful planning, diligent material acquisition, and meticulous construction, you can create a valuable and aesthetically pleasing addition to your property, maximizing its impact and providing a functional storage solution for years to come.

0 comments:

Post a Comment