Building a Lean-To Shed on a Budget: A Practical Guide

So, you're dreaming of a lean-to shed â€" that extra space for tools, bikes, or maybe just a quiet spot to escape the chaos? But the thought of the cost is giving you a headache? Don't worry, you're not alone! Building a lean-to shed doesn't have to break the bank. With a little planning and some DIY elbow grease, you can create a functional and affordable addition to your property. This guide will walk you through the process, focusing on cost-effective strategies every step of the way.

Planning Your Lean-To Shed: The Foundation of Success

Before you even think about hammering a nail, you need a plan. This is where you’ll save yourself time, money, and potential headaches down the line. Seriously, don't skip this part!

Determining Size and Location:

How much space do you *really* need? A smaller shed is cheaper and easier to build. Measure the area you’re considering and sketch it out. Think about access â€" will you need a wide enough opening for larger items? Consider the sun exposure â€" do you need shade or sunlight? And most importantly, check local building codes and regulations before you even start digging!

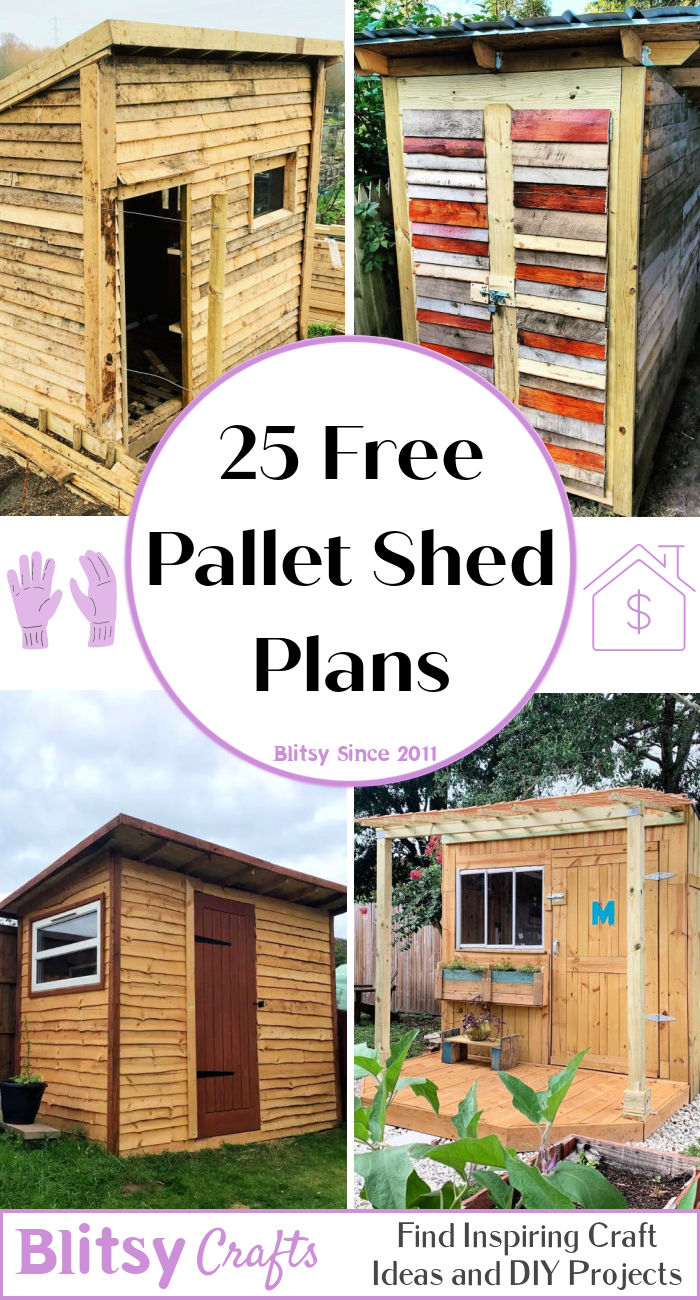

Choosing Your Materials:

This is where you can really make or break your budget. Recycled or reclaimed materials are your best friend. Check online classifieds, salvage yards, or even ask neighbours if they have any lumber or roofing they’re getting rid of. You might be surprised at what you can find! If you need to buy new, consider pressure-treated lumber for the base and framing â€" it’s more expensive upfront, but it’ll last longer and save you money in the long run. For roofing, corrugated metal is durable, relatively inexpensive, and easy to work with.

Creating a Detailed Budget:

List every single material you'll need, research prices at your local hardware stores, and factor in any tools you might need to rent. Don't forget to add a buffer for unexpected costs â€" things always pop up! Having a clear budget will keep you on track and prevent overspending.

Construction: Building Your Lean-To Shed

Now for the fun part (well, maybe)! Remember, safety first! Wear safety glasses, work gloves, and sturdy boots. If you’re not comfortable with any aspect of the construction, don't hesitate to ask for help or consult a professional.

Building the Foundation:

A simple concrete slab is ideal, but you can also create a gravel base. For a gravel base, level the ground, lay down landscape fabric to prevent weeds, and then add a layer of compacted gravel. This is a much cheaper option than concrete but might not be as durable.

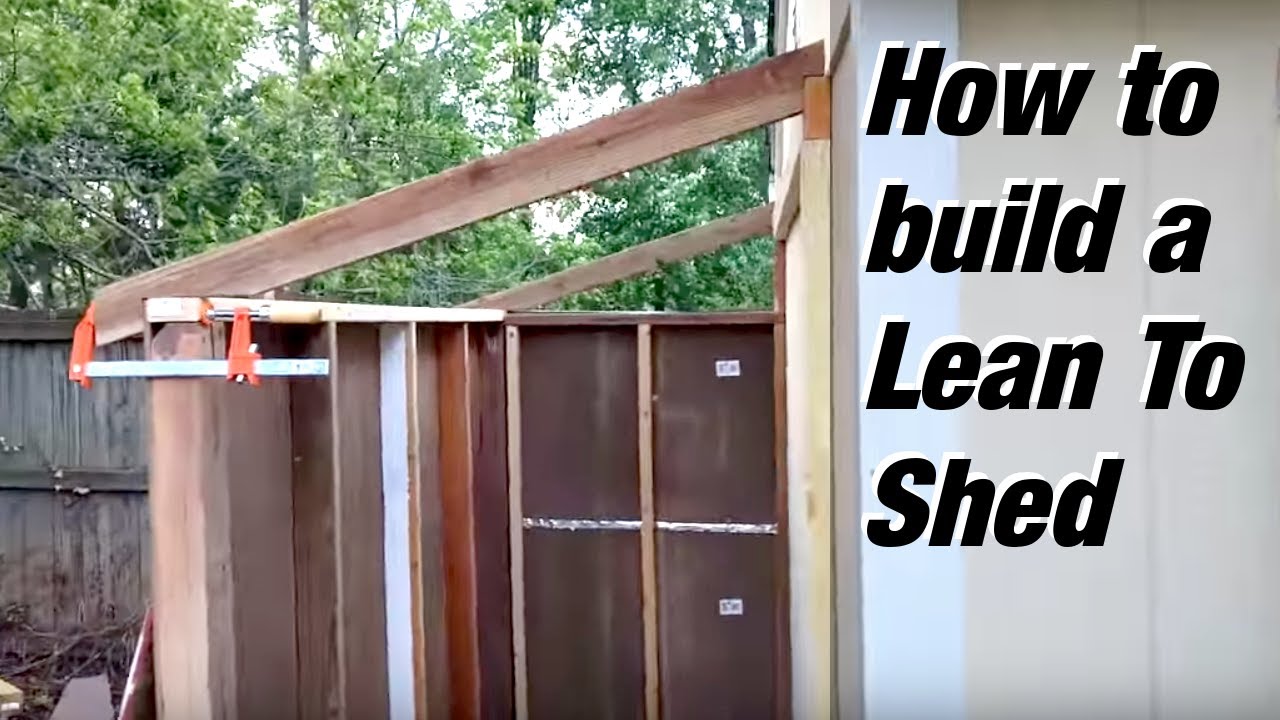

Framing the Walls and Roof:

This step requires some basic carpentry skills. Cut and assemble the frame according to your plan. Ensure everything is square and level using a level and speed square. Remember, accurate measurements are crucial for a stable structure. Don't rush this part!

Installing the Roofing:

Attaching the roofing material is fairly straightforward, especially with corrugated metal. Make sure to overlap the sheets correctly to prevent leaks. Use appropriate fasteners and seal any gaps with roofing sealant to ensure a watertight seal. Consider adding a small overhang to protect the walls from rain.

Adding the Finishing Touches:

Once the main structure is complete, you can add finishing touches like a simple door, a window for ventilation, or even some shelving. These are optional additions, but they can enhance the functionality and appearance of your shed.

Saving Money During Construction

Here are some additional tips to keep your costs down:

- Borrow tools from friends or family instead of renting or buying them.

- Shop around for materials and compare prices at different suppliers.

- Consider using salvaged lumber for non-structural parts like shelving.

- Enlist the help of friends or family to reduce labor costs.

- Do the work yourself! This is the biggest cost saver of all.

Building a lean-to shed is a rewarding project that can greatly enhance your property without emptying your wallet. By carefully planning, sourcing materials wisely, and prioritizing safety, you can create a functional and affordable storage solution that meets your needs.

Commonly Asked Questions

Here are some questions people frequently ask about building lean-to sheds:

Q: Do I need a building permit for a lean-to shed?

A: This depends entirely on your local building codes. Some areas require permits for structures of any size, while others have size limits. Always check with your local authorities before starting construction.

Q: How long does it take to build a lean-to shed?

A: The time it takes varies depending on the size and complexity of the project. A simple lean-to can be built in a weekend, while a more elaborate design might take several days or even weeks.

Q: What’s the best type of wood to use?

A: Pressure-treated lumber is a great choice for the frame as it resists rot and insects. For less critical parts, you could consider using other less expensive lumber, but always ensure it's properly treated for outdoor use.

Q: Can I build a lean-to shed against my house?

A: Yes, you can, but be sure to check your local building codes and ensure proper drainage to avoid any moisture problems for your house.

Q: What if I don’t have any carpentry skills?

A: Start with a simple design, and don't be afraid to ask for help from friends or family who are more experienced. There are also plenty of online resources and videos that can guide you through each step of the process. Consider starting with a smaller project to gain confidence before tackling a larger one.

Remember, even a small lean-to shed can significantly improve your property. With careful planning and execution, you can build a functional and affordable structure that will last for years to come. Happy building!